Typical challenges in industrial process applications are:

- Yield optimization by stringent process control in critical manufacturing steps

- Mitigation of product scrapping

- Real-time quality control

- Process reaction control to minimize giveaway

- Purity control in both intermediate and final manufacturing stages

- Safety control and energy savings

AVL’s online infrared technology facilitates multi-parameter measurements, providing real-time data on various gas components. FTIR technology is crucial for detecting and quantifying unwanted pollutants down to parts-per-billion (ppb) levels, ensuring high purity standards throughout the process.

In green hydrogen production, purity control is vital. Online measurements of CO and CO2 using NDIR technology are essential to exclude unwanted carbon sources in water, ensuring the highest quality hydrogen production.

To measure total organic compounds, AVL employs Flame Ionization Detectors (FID). This technology is highly effective in quantifying organic compounds in the gas stream, ensuring that any potential contaminants are identified and controlled. This is particularly important in processes where the presence of organic compounds can significantly impact on the final product quality. By integrating these advanced analytical technologies, AVL's process analytics solutions provide comprehensive monitoring and control, ensuring the highest standards of purity in automated manufacturing processes.

AVL’s analytical solutions enhance safety by providing precise gas measurements, reducing the risk of hazardous leaks and ensuring safe working conditions. They help monitoring and controlling gases to reduce emissions. Additionally, AVL's advanced analyzers ensure high product quality by detecting impurities and optimizing production processes, leading to consistent and reliable outputs.

Accurate and Reliable

Highly accurate FID with very low detection limit and a rise time <2 sec, best-in-class CLD quench specification.

Flexible and Adaptable

Superior FTIR with a spectral resolution of 0.5 cm-1 and dedicated FTIR evaluation methods for diverse applications.

Low Cost of Ownership

Avoiding operation gases like synthetic air for FID, pure O2 for CLD, and no liquid N2 for FTIR analyzers.

Easy Operation

Stay connected anywhere and anytime thanks to web-interface operation.

Chemicals and Petrochemicals

AVL gas analyzers offer advanced solutions for process control and emission monitoring in chemical plants. They provide precise measurements of key gases, ensuring both compliance with environmental regulations and process optimization. These systems enhance operational efficiency, optimize production yields and also contribute to reduce emissions, for a cleaner and safer industrial environment. They are typically used in applications like:

- Bulk chemicals

- Petrochemicals manufacturing plants

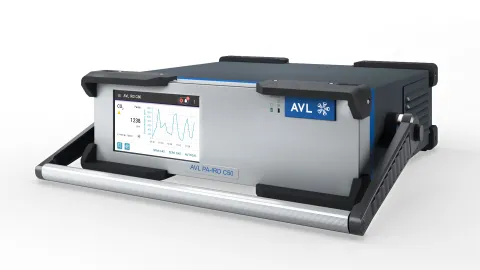

The AVL FTIR C50™ is a multi component measuring system for emission monitoring and industrial process applications.

The AVL PA-FTIR C50™ is a compact and lightweight FTIR analyzer for emission monitoring in the process industry.

The AVL PA-FID C50 is a portable FID analyzer for continuous total organic carbon measurement in the process and aviation industry as well as in laboratories.

The AVL IRD C50™ is a high-precision NDIR and NDUV analyzer for continuous and periodic measurements of up to seven gaseous components from combustion and industrial processes as well as power generators.

Industrial Gases

AVL gas analytics enhance process control in industrial and specialty gas segments. AVL provides precise measurements, ensuring optimal performance and safety. AVL analyzers also enhance high purity levels in specialty gases, crucial for various industrial applications.

AVL NDIR/NDUV analyzers measure gas concentrations with non-dispersive infrared/ultraviolet detectors and are ideal for CO, CO2,SO2, NO, NO2, CH4 and other hydrocarbons. AVL FTIR analyzers measure multiple gases simultaneously with Fourier Transform Infrared technology. It is particularly suitable for trace impurities in specialty gases. AVL analyzers serve industrial gas processes like:

- Air Separation Units (ASU)

- Steam Methane Reforming (SMR) Units

- Specialty Gases

The AVL FTIR C50™ is a multi component measuring system for emission monitoring and industrial process applications.

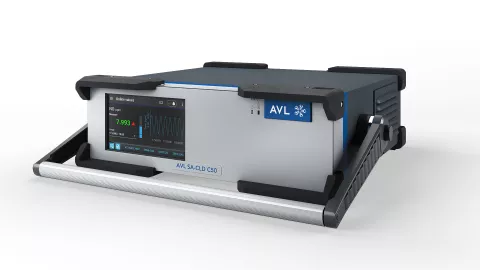

The AVL CLD C50™ is a light-weight Chemiluminescence Detector for stand-alone use in indoor areas or as a stack analyzer in emission measurement systems.

The AVL IRD C50™ is a high-precision NDIR and NDUV analyzer for continuous and periodic measurements of up to seven gaseous components from combustion and industrial processes as well as power generators.

The AVL iCAL GDU SL™ is a portable gas divider for linearity verification of gas analyzers.

High-end hydrogen mass spectrometer to support the development of electrolyzers and fuel cells (FC). It measures H2 and optionally N2, O2, H2O and CO2.

Hydrogen

AVL gas analytics enhance hydrogen segment applications by optimizing for instance electrolysis processes and ensuring quality control. We provide precise measurements for:

- Fuel cells

- Electrolyzers

- High purity hydrogen for transportation and storage.

These solutions improve process control, boost performance, and help to comply with stringent purity standards.

Oil and Gas

AVL gas analytics enhance process control in the oil refining industry and natural gas purification processes. AVL analyzers provide precise measurements which help to optimize operations and ensure compliance with environmental standards. In transportation and distribution networks, AVL solutions can monitor quality of natural gas as well as impurities and help to improve safety and efficiency. AVL serves industries like:

- Oil Refinery Industry

- Natural Gas Purification

- Natural Gas Transportation & Distribution Networks